Industry 4.0 in an offset printing house

How automation and digitalization of processes impact the quality and efficiency of packaging production

Advanced manufacturing technologies in an offset printing house specializing in packaging and leaflet production for the pharmaceutical, dietary supplement, and cosmetics industries are crucial for enhancing competitiveness and staying at the forefront of innovation. In an era of intensive digitalization and growing consumer expectations, the printing industry faces the challenge of producing top-quality packaging that not only meets aesthetic requirements but also aligns with sustainable development trends.

Automation of production processes, a key pillar of the Industry 4.0 concept, plays a vital role in this context, allowing cosmetic packaging manufacturers to achieve greater efficiency, precision, and flexibility. This, in turn, guarantees customers that packaging and leaflets are produced with the utmost care. As a result, there are fewer complaints, eliminating delays and costs associated with production downtime.

The report “Digitalization Productivity Bonus: Sector Insights” analyzed four key industrial areas where the adoption of new technologies can bring significant benefits to the sector. One of these is the printing, packaging, and paper industry.

The question is: How exactly do these systems, machines, technologies, and monitoring improve packaging production quality, and what benefits do cosmetic industry clients gain?

Automation as the future of the printing industry

Industry 4.0, or the Fourth Industrial Revolution, signifies the integration of modern technologies such as artificial intelligence (AI), robotics, and data analytics with traditional manufacturing processes. In cosmetic packaging production, automation plays a crucial role in enabling efficient collaboration between people, machines, and systems.

Automated production lines equipped with sensors, cameras, and advanced control systems allow continuous monitoring and optimization of production processes. As a result, machines can independently detect and correct errors, minimizing the risk of defective packaging and leaflets. This ensures high product quality while reducing production time, ultimately leading to lower packaging costs.

Enterprise-wide automation is an essential development factor that streamlines information flow both within the company and in client relationships. This facilitates more rational decision-making and more effective management. Automation enhances productivity, eliminates human errors, and significantly increases operational speed and the ability to meet customer needs. Proper implementation of these processes benefits not only packaging manufacturers but also cosmetic companies outsourcing their packaging and leaflet production.

What benefits does automation and digitalization of packaging production bring to lients?

New technologies are transforming the modern printing industry. Omnipresent digitalization and automation streamline many pre-production processes, such as imposition, file verification, and plate creation. In the press department, automation aids in initial setup, color management, and machine operation during printing, which is influenced by numerous external factors. Additionally, measuring the consumption of raw materials needed for printing is crucial. Many machines have dedicated modules that fully support the operator’s work.

Data analysis also reveals time savings and enables the implementation of innovative IT systems that improve the economic efficiency of printing production. With network connectivity, access to multiple devices is available from almost anywhere in the world, providing real-time monitoring of machine settings and performance.

Automation in the printing industry offers numerous advantages to clients ordering packaging production, including:

- Significant increases in work efficiency, accelerating order fulfillment.

- Cost optimization, reducing the final price of packaging and leaflets.

- Greater precision in executing individual tasks, ensuring top quality and eliminating production errors.

Fewer errors = fewer complaints = an efficient order fulfillment process = products reaching store shelves on time.

Quality under control

Quality is one of the key aspects of cosmetic packaging production. Customers expect packaging to be not only aesthetically pleasing but also durable, safe, and functional. Automation of production processes plays an essential role in achieving high standards in various ways.

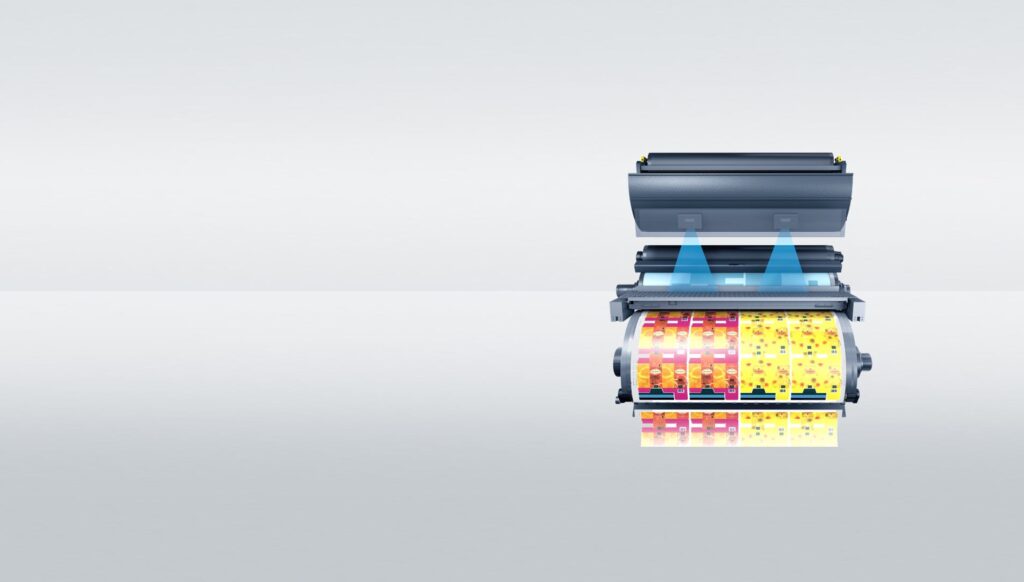

Investments in modern machinery, advanced software, and production technologies are necessary for printing houses to meet the highest requirements. Automation not only speeds up processes but also minimizes the risk of errors. Printing machines from reputable manufacturers are equipped with advanced control systems that monitor printing quality in real time.

For example, the Prinect Inpress Control system automatically monitors color stability without operator intervention. The color deviation ΔE is continuously displayed and adjusted without removing sheets, ensuring high efficiency while reducing work time and energy consumption.

Furthermore, the Prinect Inspection Control system provides comprehensive quality control for every printed sheet. During production monitoring, the system continuously compares printed sheets with a “digital reference card.” Two high-resolution cameras inspect each sheet, detecting printing errors and preventing further costs. For the pharmaceutical and cosmetic industries, where both product safety and aesthetic execution are critical, ensuring that packaging content matches the provided file is essential.

Professional printing houses guarantee top quality at every production stage. Early error detection helps avoid costly complaints and delays in product distribution. Integrated quality control systems monitor production parameters such as material thickness, color accuracy, and finishing, responding immediately to any deviations.

By analyzing data collected at each production stage, packaging manufacturers can better understand potential issues and implement improvements to prevent recurrence. This leads to more consistent and optimized packaging quality. For cosmetics manufacturers outsourcing packaging production, this is a guarantee that their products will be perfect and delivered on time, allowing them to focus on core priorities such as expanding their portfolio and meeting consumer expectations.

Efficiency and flexibility in production

Automation significantly enhances the efficiency and flexibility of cosmetic packaging production by shortening production times, eliminating downtime, and reducing raw material and energy consumption. One of the key elements of Industry 4.0 is production flexibility, which, through intelligent control systems, enables rapid adaptation of production lines to different types of packaging without lengthy retooling. This is especially important in the cosmetics industry, where diverse packaging designs are the norm.

The implementation of modern systems delivers outstanding results, with software playing an increasingly important role in daily printing operations. While technology automates many time-consuming tasks, human expertise remains crucial to fully leverage its potential.

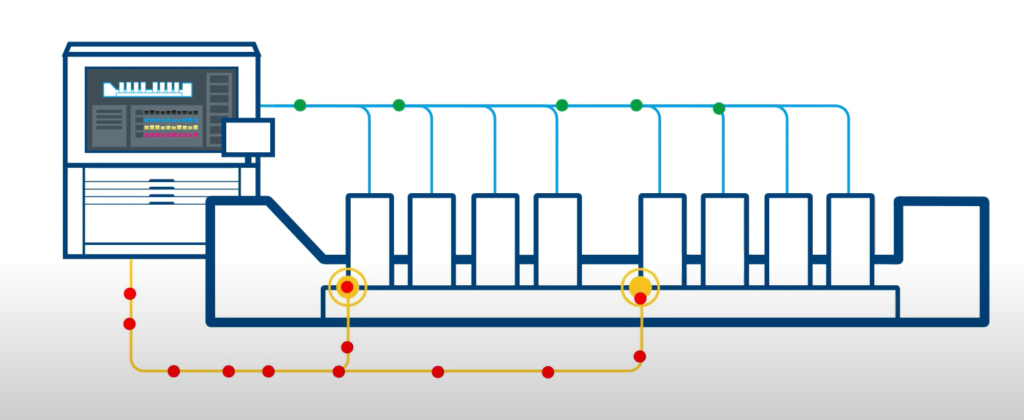

From a technical perspective, printers now have access to software that monitors and diagnoses machine conditions, automating many processes. This allows for quick access to information about equipment status, material usage, and performance metrics over a given period. As a result, production planning and resource management become more efficient. Technologies also enable direct loading of print-ready files and remote monitoring of print job queues.

Technology for sustainable development

Modern machines are more environmentally friendly, consuming less energy. Combined with automation, this makes cosmetic packaging production more sustainable. Companies can manage their production processes more efficiently and ecologically. Automation, along with advanced monitoring and data analysis systems, enables precise resource planning, leading to optimization and waste minimization.

For example, intelligent resource management systems adjust material usage based on current production needs, eliminating overproduction and reducing waste. Digital tools also facilitate monitoring the entire packaging lifecycle—from design to production and distribution—allowing for further improvements and reductions. These solutions help companies lower production costs while meeting increasingly strict environmental regulations and growing consumer expectations regarding sustainability.

By implementing advanced technologies in cosmetic packaging production, companies take a significant step toward a more responsible and sustainable future, harmonizing innovation with environmental care.

Systems for efficient print file preparation

With the development of the industry, advanced platforms for resource management, production file processing, soft proofing, and automation of printing processes are emerging. The main advantage of these systems is not only the acceleration of graphic file preparation for printing but also complete control and secure communication with the client.

Thanks to their modular structure and almost full configurability, such systems can be precisely tailored to the specific needs of a printing house, its technological processes, and work style. However, to achieve the expected results, system implementation must be preceded by a thorough analysis and examination of existing processes. Only in this way can it be ensured that the new technology truly improves production efficiency and increases customer satisfaction.

Efficient printing house operations rely on streamlining all stages—from packaging design, file preparation and ripping, plate exposure, to the preparation of inspection and CIP3 files. One of the key advantages of these systems is their ability to integrate with other tools already present in the company. It is crucial that the implemented solutions are compatible and support each other rather than conflict. The goal of implementation is to shorten working time and increase the efficiency of teams at every stage of production, including:

- Development of technology and methodology before the order is sent to production,

- Better allocation of tools in production,

- Automatic creation of bleed areas,

- Optimal use of resources through efficient data flow.

Software for efficient client communication and full process control in printing houses

Aby sprostać wymaganiom klientów i usprawnić współpracę, drukarnia powinna wdrażać nowoczesne platformy i systemy do zarządzania zasobami, To meet customer demands and improve cooperation, a printing house should implement modern platforms and systems for resource management, production file processing, soft proofing, and process automation. A key benefit for customers is the acceleration of the file approval process, significantly reducing order completion time.

Beyond process automation and quality control, software supporting customer communication is an invaluable tool that enhances information security and improves the customer experience when working with a printing house. Implementing collaboration-supporting systems creates a more efficient and convenient order fulfillment path. For clients, this means a faster file approval process and easier access to complete information at every stage of order execution.

The introduction of innovative solutions in printing houses brings numerous benefits to clients, including:

- Optimized administrative and production processes, shortening order fulfillment time,

- Access to a complete history of changes and execution,

- Full control over the process, eliminating the risk of printing incorrect files,

- Fast information and file exchange for approval, available 24/7 in one place,

- Handling of PDF files with preview of color separations, trapping, rasterization, and proofing, carried out through automated cloud-based processes.

All these advantages translate into faster and more efficient order fulfillment for packaging and leaflets in the cosmetics industry. The best approach to implementing new systems is to do it in stages, allowing clients to gradually familiarize themselves with the possibilities and facilitate daily operations. Although new technologies may raise concerns, the printing house’s role is to provide appropriate training, implementation support, and continuous assistance. Listening to customer feedback and responding to their input is key to further system development. Thanks to modern solutions, the printing house aims to ensure that cooperation with clients is fast, easy, and secure.

Tools for product protection against counterfeiting

In addition to print tracking systems, clients in the pharmaceutical and cosmetics industries seek to protect their products from counterfeiting. This is especially crucial for expensive and original products.

To meet these needs, printing houses offer various methods of protection against copying and counterfeiting, which not only confirm the authenticity of the print but also ensure full control over the location and conditions of production.

One popular protection method is microprinting, allowing the placement of tiny, difficult-to-notice texts or symbols in the packaging or leaflet design. This is an effective way to mark, identify, and verify the authenticity of products.

Professional software used in printing houses for preparing offset printing files includes functions unavailable in standard graphic programs. These tools, besides converting graphic forms into print plate images, enable the creation of original and difficult-to-replicate elements in printed materials. Even if someone notices these elements and attempts to copy them, a lack of complete technical knowledge will make accurate reconstruction impossible.

Thanks to advanced programs and technologies, printing houses can not only control print quality and accuracy but also offer clients additional options that protect their brand from counterfeiting.

SUMMARY

Given the dynamic market changes and increasing demands of clients in the cosmetics industry, investing in modern technologies is becoming crucial for packaging printing houses. Participating in industry fairs and conferences allows decision-makers to learn about the latest machines and technologies that may become the foundation for future investments. The introduction of automation and digitization in production processes is revolutionizing the cosmetics packaging industry, offering tangible benefits in terms of higher quality, efficiency, and production flexibility. Advanced technologies enable printing houses to better respond to market needs while supporting sustainable development and building a competitive advantage.

Besides technologies directly related to machinery and the production process, there are also solutions that allow integrated management of the entire printing house—from customer contact, order acquisition, job queue and material management, to production and project execution. And all this can be done remotely, from anywhere and at any time. Order and task information is available in one clear view.

Automation and digitization in printing, as elements of Industry 4.0, support the continuous development of businesses. Streamlining key work stages (prepress, press, postpress) as well as surrounding processes (related to raw material control, machine operation, logistics, and supply chains) and customer service is the direction for many printing facilities. This is the future happening now.

Therefore, when choosing a partner for packaging and leaflet production, it is also worth considering whether the printing house is developing, understands market needs, and invests in modern technologies. This is undoubtedly a distinguishing factor that will ultimately translate into higher product quality, execution efficiency, reduced costs associated with complaints, and better, safer communication.

Przeczytaj także...

See more entries

What awaits the packaging market in 2025?

How packaging can influence the success of a dietary supplement?